Vermiculture - The Pioneering Work

The basic research work carried out by Morarka Foundation in vermiculture technology development & its dissemination had given it a new identity. Today we are known for vermiculture not only in India but also outside the country.

Vermiculture Technology Development

Context:In late 1980s and early 1990s agricultural scientists in the world realized the limitations of chemical fertilizers used for fertility management. While on one hand research was initiated to improve the use efficiency of chemical fertilizers, on other hand alternative inputs were also considered.

Organic matter recycling has been in use in India for centuries. In 19th and 20th century scientific methods for converting low value organic matter into high value organic composts were developed. The activities of earthworms for recycling of organic matter became the focus of attention by scientific community in mid-1990s.

Development:Initially vermiculture i.e. use of surface living earthworms was carried out at a very small scale-mainly for management of kitchen wastes& for fish baits in Europe. In 1994-95Morarka Foundation began with 100 earthworms of Eiseniafoetida species to develop a commercial process of vermiculture. This pioneering effort enabled Morarka Foundation to become the single largest producer of vermicast in 1998, a position which it still enjoys.

Initially the production was managed through its own and entrepreneurial network of production units. Slowly Morarka Foundation handed over complete production to entrepreneurs.

In 20 years since its development by Morarka Foundation, today each and every program / developmental scheme of any State and or Central Government necessary include vermiculture as a component.

Technology: The most important reason for the success of vermiculture is the simplicity of methods. The Foundation managed to convert a very complex science in to a very simple and easy to do method which required very little facilities, tools and inputs.

Windrows Method:This is the simplest way to do vermiculture:

1.Requires very low initial investment.

2.Can be done on the farm even in open areas under the tree shed.

3.Wide range of organic matters can be used as raw material.

4.High earthworms multiplication rate of 10-12 times in a year.

5.Unit could be better produce upto 100,000 kgs vermicast in one year.

Windrows Method - Process Development:Pictorial explanation of the method.

|

|

|

Raw material for vermiculture |

Earthworm life cycle stages |

Vermicast production at farm |

|

|

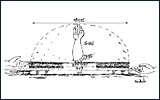

Windrows - dimensions |

Charged windrows |

|

|

|

Windrows being covered |

Vermicast being recovered |

Final removal of vermicast |

|

|

Replaying of vermicast windrows |

Vermicast being sieved |

Vermiculture Know-how Dissemination

Beginning in 1995-96 itself, Morarka Foundation involved farmers to participate in the research work. By the time know-how (windrows method) was established in 1997 about 4,000 farmers had started producing vermicast.

From 1997-98 onwards, many government agencies such as Directorate of Agriculture, Watershed Department, DPIP, Department of Biotechnology, etc. supported the know-how dissemination.

Subsequently, beginning in the year 2000, entrepreneurs came forward to setup large size commercial units. During this period many cattle relief organizations - Gaushalas had also started vermiculture to earn enough to sustain their cow protection efforts.

Over the years, vermiculture production units was also setup as "Common Facility Centres" by groups of farmers in villages.

Vermiculture production quickly became a major component of agri-business models across the country.

In less than ten years, Morarka Foundation has already created over 1,000,000 Metric Tonnes annual production capacity of vermicast in India. The progress of know-how dissemination is given below:

Progress of Know-how Dissemination

| Year |

Cumulative Individual Farm Units and their Annual Production Capacities |

Cumulative Commercial Units by Entrepreneurs, Gaushalas, CFC's and their Annual Production Capacities |

Cumulative Total Production Capacity (in Metric Tonnes) |

Remarks |

| Number |

Production Capacity (in Metric Tonnes) |

Numbers |

Production Capacity (in Metric Tonnes) |

| 1995 |

150 |

100 |

- |

- |

100 |

The Research work commenced with farmers as partners. |

| 1996 |

500 |

800 |

2 |

200 |

1,000 |

Research Center cum production units were setup. |

| 1997 |

4,000 |

4,000 |

5 |

1,000 |

5,000 |

Diversified production facilities were setup. |

| 1998 |

15,000 |

20,000 |

10 |

5,000 |

25,000 |

Expanded the production base. |

| 1999 |

40,000 |

40,000 |

50 |

10,000 |

50,000 |

Achieved improved production efficiences. |

| 2000 |

75,000 |

70,000 |

100 |

15,000 |

85,000 |

Major expension of farm units was undertaken. |

| 2001 |

1,20,000 |

1,50,000 |

200 |

25,000 |

1,75,000 |

Viability of business units was established. |

| 2002 |

2,00,000 |

2,50,000 |

220 |

30,000 |

2,80,000 |

Consolidated the growth. |

| 2003 |

3,50,000 |

6,50,000 |

300 |

3,50,000 |

10,00,000 |

Major expansion in new areas has been attempted. |

| 2004 |

5,00,000 |

10,00,000 |

500 |

5,00,000 |

15,00,000 |

Reasonable level of commercial viability has been established. |

| 2005 |

10,00,000 |

20,00,000 |

2,500 |

20,00,000 |

40,00,000 |

This become an independent operation. |

| 2006 |

Expected |

70,00,000 |

Mostly by our partners and enterpreneurs. |

Know-how dissemination services are now offered through our own initiatives as well as through the efforts of our partners, mostly by training to individual farmers as a component of organic farming programs.

Vermicast Specifications

Vermicast Physical Quality Parameters

- Vermicast is a dark brown/black humus like coarse material, soft in feel and free from any foul smell, live weed seeds and other contaminations.

- Mucus type substance coated on each particle, that increases aeration in the soil, provides excellent water retention properties and improves the drainage in heavy soils.

- Contains sufficient moisture (25-35%) at the time of packing to ensure high level of biological activities.

Vermicast is one of the best form of organic manure and is practically 100 percent like humus.

Vermicast Chemical Parameters

S.

No |

Parameters |

Vermicast Normal Range |

| 1. |

pH |

6.5 - 7.5 |

| 2. |

Organic Carbon (%) |

15 - 20 |

| 3. |

Nitrogen (%) |

1.3 - 1.7 |

| 4. |

Phosphorus (%) |

1.2 - 1.8 |

| 5. |

Potassium (ppm) |

800 - 1850 |

| 6. |

Carbon : Nitrogen |

14 - 15 : 1 |

| 7. |

Calcium % |

3.0 - 4.5 |

| 8. |

Magnesium % |

0.4 - 0.7 |

| 9. |

Sodium (ppm) |

400 - 500 |

| 10. |

Sulphur (%) |

0.003 - 0.04 |

| 11. |

Iron (%) |

0.3 - 0.7 |

| 12. |

Zinc (%) |

0.028 - 0.036 |

| 13. |

Manganese (%) |

Traces to 0.04 |

| 14. |

Copper (%) |

0.0027 - 0.0123 |

| 15. |

Boron (%) |

0.0034 - 0.0075 |

| 16. |

Aluminum (%) |

Traces to 0.071 |

| 17. |

Cobalt, Molybdenum |

In available form | |

|

Vermicast provides complete range of macro, secondary and micro nutrients.

Vermicast Biological Parameters

S.

No |

Parameters |

Vermicast Normal Range |

| 1. |

Nitrogen Fixing Bacteria (cells/gm) |

2.5 * 10 6 |

| 2. |

Phosphate Solubilizing Microbes |

In sufficient

quantities |

| 3. |

Beneficial Fungi (spores incl.) |

In sufficient

quantities | |

|

Beneficial bacteria and fungi in vermicast introduces very high level of biological activities in the soil.

Vermicast Enrichment for Quality Improvement

S.

No |

Parameters |

Vermicast Normal Range |

| 1. |

pH |

6.5 - 7.5 |

| 2. |

Organic Carbon (%) |

20 - 35 |

| 3. |

Nitrogen (%) |

1.8 - 2.5 |

| 4. |

Phosphorus (%) |

1.5 - 2.5 |

| 5. |

Potassium (ppm) |

1200 - 2500 |

| 6. |

Carbon : Nitrogen |

14 - 15 : 1 |

| 7. |

Calcium % |

3.0 - 4.5 |

| 8. |

Magnesium % |

0.4 - 0.7 |

| 9. |

Sodium (ppm) |

500 - 1000 |

| 10. |

Sulphur (%) |

0.03 - 0.07 |

| 11. |

Iron (%) |

0.3 - 0.7 |

| 12. |

Zinc (%) |

0.04 - 0.05 |

| 13. |

Manganese (%) |

Traces to 0.04 |

| 14. |

Copper (%) |

0.01 - 0.03 |

| 15. |

Boron (%) |

0.005 - 0.009 |

| 16. |

Aluminum (%) |

Traces to 0.071 |

| 17. |

Cobalt, Molybdenum |

In available form | |

|

Use of biotechnology has enabled enhancement of any desired nutrients in vermicast.